A pyrolysis plant is a machine that is used to convert various types of wastes, such a plastics, biomass waste, oil sludge, and used tires into useful commodities. With the right setup, it is possible to obtain fuel oil from all sorts of non-biodegradable materials without producing any pollution. As a result, waste disposal facilities that invest in pyrolysis technology are able to increase the profitability of their operations considerably.

A popular use for pyrolysis reactors is to recycle scrap tires. Instead of sending used car tires to landfill sites and waste incinerators, a rubber pyrolysis plant can transform the waste rubber into fuel oil, combustible gas, steel wire, and carbon black. All of those products are valuable in the global commodity marketplace. Carbon black, for example, is sought-after by the pharmaceutical industry and metal refinery sector.

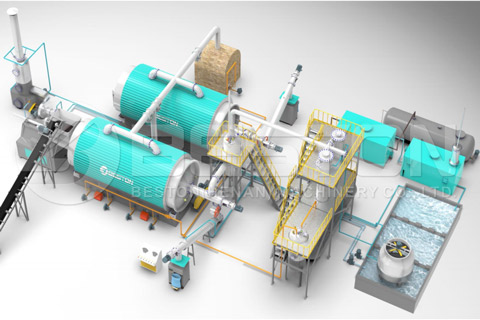

One of the leading manufacturers in the pyrolysis plant market is Beston Компания. The manufacturer produces four different plant models: the BLJ-6 and BLJ-10, which have a batch working method, and the BLJ-16 and BLL-20, which have semi-continuous and fully continuous working methods respectively. The daily capacity of Beston’s pyrolysis plants ranges from 6 tons to 24 tons. All the plants can run on a selection of heating materials from wood to charcoal to natural gas to LPG and more.

Now let’s talk about one of the features that separate the manufacturer from others in the field. The “Three in One” system that Beston employs in their pyrolysis plants means that the condenser, oil tank, and hydro seal are all part of one integrated component. Such as system has many benefits including smaller area requirements, enhanced operating safety, simple assembly, efficient condensation effect, low transportation costs, easy maintenance, and no clogging. The “Three in One” design is unique to Beston Machinery and it has been tested extensively. It is one of many reasons why the manufacturer is the number one choice for pyrolysis units around the world.

Another unique design feature of Beston’s pyrolysis plants (Beston пиролизное оборудование) is the dedusting systems, which contain water washing, ceramic ring adsorption, activated carbon adsorption, and water spray cleaning technologies. The systems work to ensure that no dust from the reactor system is emitted into the atmosphere. The activated carbon adsorption tower is an optional extra for customers that live in areas with higher emission standard regulations. When customers contact the manufacturer to obtain a price quote for a pyrolysis reactor, they will be able to learn more about the best plant configuration for their operations. Beston allows for a lot of customization form buyers.

So, if you are looking for a high-quality zero-pollution waste tire pyrolysis plant, Beston Machinery is the company to contact. They are one of the top sellers of pyrolysis reactors in China and they can customize equipment configurations to match a customer’s pyrolysis plant business plan. What’s more, they ship to worldwide locations. Some of the manufacturer’s biggest customers are located in Brazil, the Netherlands, Turkey, Romania, United Kingdom, Indonesia, South Korea, and the Phillippines.