Recycling has emerged as a high-growth industry across the world. Many entrepreneurs have made a fortune in this industry as governments all around the world focus on reducing waste and the only way to ensure that landfills do not keep filling up is to find a profitable way to recycle things. Waste tires are a big problem and thankfully, these can be easily recycled with the help of pyrolysis process.

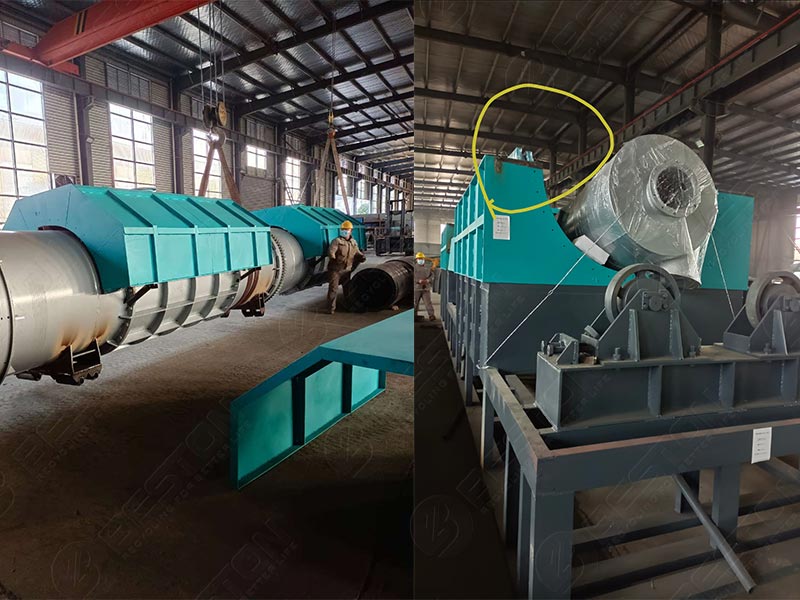

This is why, pyrolysis tire recycling plants(planta pirólisis llantas) have a huge demand across the globe. These plants are designed to break down the chemicals making up tires into simpler products such as fuel oil and carbon black. Recovering fuel oil and carbon black from waste tires is a profitable business process, but success in this business depends heavily on the technology used in the pyrolysis plant. Here is everything you need to know about choosing the right pyrolysis tire recycling plant.

Choose the Latest Technology

Essentially, it’s a technology business. On the surface, it might seem like a typical recycling business but at its heart, it’s all about technology. Using better technology than your competitors will give you an edge over the competition, and that, in turn, will ensure the long-term success of your business. Successful businesses in this industry continue to invest in new technology and keep upgrading their plants in order to keep their operational costs down.

Manufacturers that continue to invest in research and development should be a preferred choice when buying a pyrolysis plant(https://www.bestoneco.com/trituradoras-de-llantas/). With these manufacturers, you will get access to the cutting-edge technology that should ultimately lead to better yield and better efficiency. This is why, it is important to buy from a manufacturer known for heavy investment in R&D.

Automation Level

You can buy these plants in various configurations, including semiautomatic and fully automatic configurations. If you have the capital, it is better to invest in a fully automatic plant as that should save quite a bit of money. Fully automatic plants(eco máquinas Beston) also offer several other advantages.

You will get better efficiency and in the long run, you will save money on labor costs. Also, fully automated plants have much lower rate of error as almost no human intervention is required in the process. Fully automated lines do cost more as compared to semiautomatic ones but eventually, you will come out on top. Complete automation also gives you an edge over your competitors.

Compliance with Local Guidelines

Machinery used for recycling needs to comply with the local pollution guidelines. Every country and in fact, even regions within a country, typically have their own guidelines to follow for businesses. You cannot afford to violate these laws as they often come up with extremely heavy fines.

Make sure the recycling plant (planta de pirolisis)you’re planning to buy complies with the local pollution guidelines. Don’t take the word of the manufacturer. Talk to other businesses in your location who have invested in similar plants in order to make sure that you wouldn’t have any problems with the local guidelines.

To conclude, recycling waste tires using pyrolysis technology is a tried and tested method. There are thousands of pyrolysis plants that are running successfully all across the globe. However, it is, at heart, a technology business and you will do well by investing in the latest technology and by continuously upgrading your plant. It is also better to invest in a fully automated plant to get the best return on your investment when buying a pyrolysis plant.