Pyrolysis technology has gained significant traction globally as an effective solution for managing waste and promoting sustainability. With advancements in pyrolysis equipment, countries like Malaysia and the UK are investing heavily in this transformative technology. This article delves into the state of pyrolysis plants in Malaysia and the UK, highlights the advantages of continuous pyrolysis plants, and examines the role of advanced pyrolysis equipment in revolutionizing waste management.

Pyrolysis Plant in Malaysia

1. Rising Demand for Waste Management Solutions

Malaysia has faced increasing challenges with waste accumulation, particularly with plastics and rubber. A pyrolysis plant in Malaysia provides an innovative solution by converting waste materials into valuable resources like pyrolysis oil, carbon black, and syngas. These byproducts not only reduce landfill reliance but also create economic opportunities.

2. Key Features of Pyrolysis Technology in Malaysia

- Adaptability to Local Needs: Malaysian pyrolysis plants are tailored to process diverse feedstocks, including municipal solid waste, end-of-life tires, and agricultural biomass.

- Environmental Compliance: Strict regulations ensure that these plants adhere to global environmental standards, minimizing emissions and promoting sustainability.

- Economic Incentives: Government support through subsidies and tax incentives has accelerated the adoption of pyrolysis technology.

3. Prominent Applications

- Energy Recovery: Pyrolysis oil and syngas are used as alternative fuels for industrial processes.

- Circular Economy: The reuse of carbon black in rubber and plastic industries exemplifies Malaysia’s commitment to a circular economy.

Pyrolysis Plant in the UK

1. Pioneering Waste-to-Energy Initiatives

The UK is at the forefront of implementing waste-to-energy technologies. A pyrolysis plant in the UK not only addresses waste management but also contributes to renewable energy generation.

2. Key Drivers for Adoption

- Stringent Environmental Regulations: The UK’s commitment to reducing landfill waste and greenhouse gas emissions has made pyrolysis technology an attractive option.

- Public-Private Partnerships: Collaborations between governments and private sectors have facilitated the establishment of state-of-the-art pyrolysis facilities.

- Focus on Plastic Waste: With increasing bans on single-use plastics, pyrolysis offers a sustainable recycling alternative.

3. Advanced Technology Integration

UK-based pyrolysis plants often integrate advanced continuous pyrolysis plant technology, ensuring uninterrupted operations and higher efficiency. These systems are capable of processing larger volumes of waste while maintaining consistent quality in byproducts.

Continuous Pyrolysis Plant: A Game-Changer

1. What is a Continuous Pyrolysis Plant?

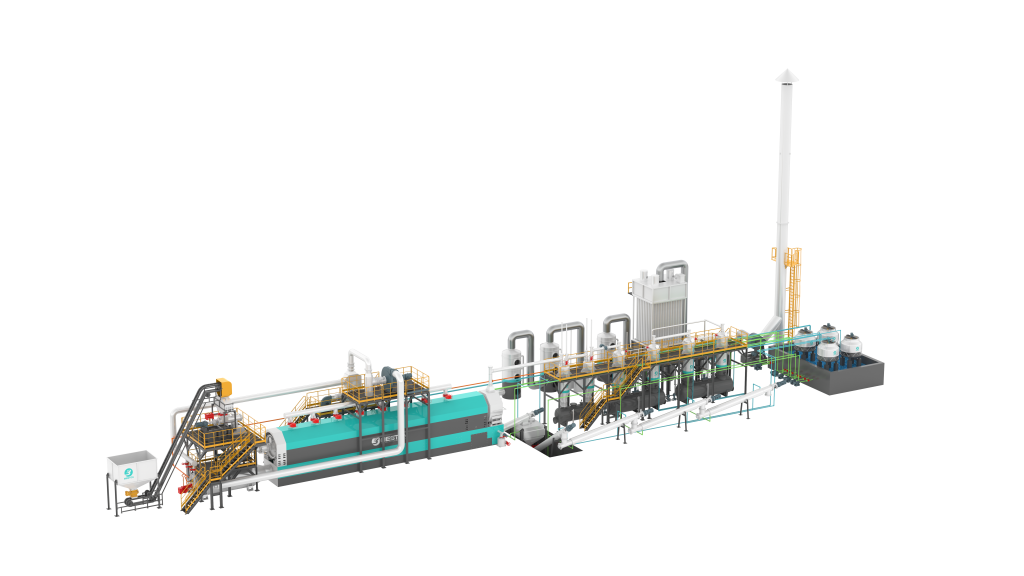

A continuous pyrolysis plant operates without the need for cooling intervals, enabling 24/7 processing of waste materials. This technology is ideal for large-scale waste management operations.

2. Advantages

- Increased Efficiency: Continuous systems ensure higher throughput compared to batch systems.

- Lower Operating Costs: Automated operations reduce labor and energy expenses.

- Enhanced Environmental Performance: Advanced emission control systems ensure compliance with environmental standards.

3. Applications Across Industries

- Plastic and Rubber Recycling: Converts end-of-life plastics and tires into valuable byproducts.

- Biomass Conversion: Transforms agricultural waste into biochar and renewable energy sources.

Pyrolysis Equipment: Driving Technological Innovation

1. Key Components

Modern pyrolysis equipment includes reactors, condensers, and emission control systems. These components work together to ensure efficient conversion of waste into usable resources.

2. Features of Advanced Pyrolysis Equipment

- Automation: Smart systems enable remote monitoring and operation.

- Durability: High-quality materials ensure longevity and reliability.

- Flexibility: Equipment is designed to handle various feedstocks, from plastics to biomass.

3. Industry Trends

- Integration with Renewable Energy Systems: Pyrolysis plants are increasingly being paired with solar and wind energy solutions.

- Digitalization: IoT-enabled pyrolysis equipment allows real-time performance tracking and predictive maintenance.

Conclusion

The adoption of pyrolysis technology in Malaysia and the UK highlights its potential to address global waste management challenges. Whether through the deployment of advanced pyrolysis equipment or the operation of highly efficient continuous pyrolysis plants, these countries are setting benchmarks in sustainability and innovation. As the demand for eco-friendly solutions grows, pyrolysis technology is poised to play a pivotal role in shaping a cleaner, greener future.