Typically, the charcoal-making machine can generate charcoal from any organic waste. People have increasingly seen the significance of biomass energy. Generally, they have discovered that there’s much money that can be generated from such equipment. And with the assistance of such a machine, you could convert organic wastes, e.g., rice husk, wood, coconut shells, and sewage sludge into fine charcoal. Besides creating charcoal that offers numerous applications, the charcoal making machine is committed to a lot in terms of environmental protection. When compared to waste landfills, it can lower the quantity of wastes by up to 95%.

Because there are many suppliers available, you need to go for a plant that implements top-of-the-line carbonization technology. Additionally, it should comprise distinct features.

What are these Unique Features to Consider in a Charcoal Making Machine?

– High production efficiency. Generally speaking, from the feeding part to discharging (minus the required duration for preheating), the entire process lasts for about 15 minutes.

– High-quality wood charcoal making machine yet affordable price. Usually, the temperature inside this charcoal carbonization furnace does not fall below 700℃. More often than not, there will be a significantly higher carbonization speed if there’s a high production capacity. For this reason, it lowers the cost.

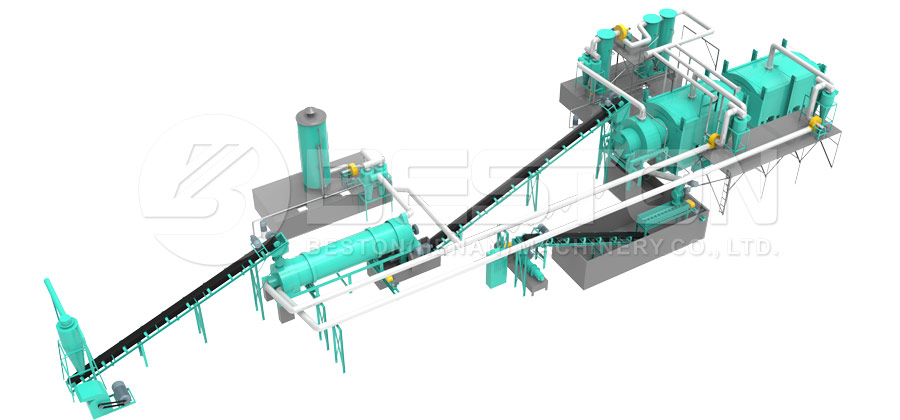

– Unique structure. The reactor generally consists of a double-layer structure. The exterior layer typically manages the drying part, whereas the interior layer handles the biomass pyrolysis plant.

– Safety features. Additionally, the charcoal-making machine is accompanied by a reliable safety design to guarantee operation safety. The following are some of the safety features:

1. The central control system primarily helps to separate the operator and the machine and guarantee safety.

2. Standard control system mainly for the power section.

3. A protective casing that helps to safeguard the operator from hurting mainly because of high temperature.

4. Professional cooling system and smoke abatement to guarantee that there’s a safe and steady discharge of flue gas.

5. Its feeding and discharging section come with a sealing device that enables a safe operation and ultimately creates a clean working place.

What Are the Benefits of Bio Charcoal?

As you might already know, bio charcoal is the main product that you’ll get from the bamboo charcoal machine. Quite frankly, the applications of this charcoal may have a few differences because the raw material changes. Nonetheless, charcoal may be applied in different fields such as in agriculture, or daily life (as fuel). What’s more, customers may sell the product to make profits. And if they’re looking to add more value, they might also reprocess them.

It’s safe to say that the charcoal-making machine offers nothing but advantages. Invest in one today and you could make significant returns from selling the products.